盤式真空過濾機(jī)用于地質(zhì)、冶金、煤炭、建材、礦山等科研實(shí)驗(yàn)單位在開展礦物可選性實(shí)驗(yàn)工作中,作為浮選、重選、磁選等作業(yè)后脫水,檢測樣品時(shí)固液分離。機(jī)器主要由真空泵、分水濾氣器、真空負(fù)壓罐及兩個(gè)過濾盤組或其排水通過自控裝置自動(dòng)排水,達(dá)到固液分離目的。本產(chǎn)品由原地礦部唯一指定企業(yè)生產(chǎn),執(zhí)行行業(yè)標(biāo)準(zhǔn)。

Disk Vacuum Filter is applicable to geological, metallurgical, building material, mining and other industries for mineral dewatering after flotation, gravity concentration, magnetic separation and other operations in tests on mineral separability and separation of solid -liquid in sample testing. It mainly comprises vacuum pump, moisture air filter,vacuum negative pressure tank and two filter trays with automatic drainage device to be provided to separate solids from liquids. The product is made by the only manufacturer designated by the former Ministry of Geology and Mineral Resources, in compliance with the Industrial standards.

| 型號規(guī)格 Model | 單位Uite | XTLZ Φ260-Φ200 |

| 濾盤直徑 Disc dia. | mm | 大盤Φ260 小盤Φ240 |

| 真空壓力 Vaccum pressure | KPA | 80 |

| 礦漿固液比Feed density | 1:(4—7) | |

| 給料粒度 Feed size | mm | ≤0.5 |

| 過濾樣品干重Dry material capa. | g | <600 |

| 過濾時(shí)間 Filter time | min | 1—10 |

| 排水時(shí)間Output water time | s | 30 |

| 濾餅水分 Cake moisture | % | <20 |

| 電 壓 voltage | v | 380 |

| 功率 Power | kw | 1.5 |

| 外形尺寸Overall Dimensions | mm | 650×540×1140 |

| 總質(zhì)量 Weight | kg | 200 |

結(jié)構(gòu)簡介

Structure

結(jié)構(gòu):XTLZΦ260-Φ200型過濾機(jī),設(shè)有兩個(gè)容量不同的濾盤,不同量的礦漿可以直接傾入相應(yīng)容量的盤內(nèi)進(jìn)行脫水處理。真空系統(tǒng)主要由旋片式真空泵、分水濾氣器、真空負(fù)壓罐、電磁閥以及真空管道組成。

1. Structure: XTLZΦ260-Φ200 filter has two filter disks with different capacities. Slurry of different amount can be directly fed into the disk with corresponding capacity for dewatering. The vacuum system is mainly composed of rotary-vane vacuum pump, water-separating gas filter, vacuum negative pressure jar, electromagnetic valve, and vacuum duct.

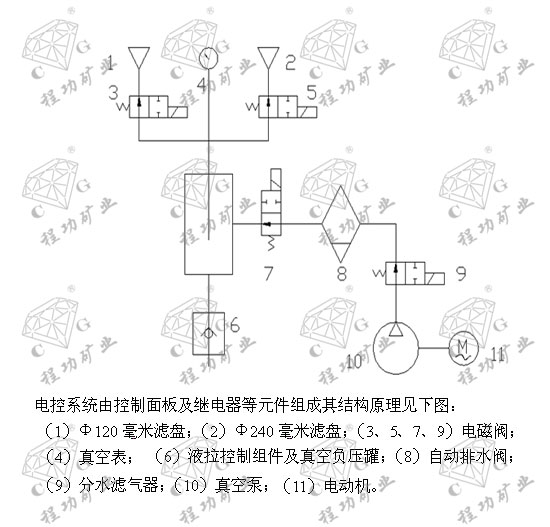

電控系統(tǒng)由控制面板及繼電器等元件組成其結(jié)構(gòu)原理見下圖:

The electric control system is composed of control panel, relay, and other components. See the figure for its structure.

(1)Φ120毫米濾盤;(2)Φ240毫米濾盤;(3、5、7、9)電磁閥;(4)真空表;(6)液拉控制組件及真空負(fù)壓罐;(8)自動(dòng)排水閥;(9)分水濾氣器;(10)真空泵;(11)電動(dòng)機(jī)。

(1) filter disk with the diameter of 120mm; (2) filter disk with the diameter of 240mm; (3, 5, 7, 9) electromagnetic valve; (4) vacuum meter; (6) hydraulic control assembly and vacuum negative pressure jar; (8) automatic drain valve; (9) water-separating gas filter; (10) vacuum pump; (11) motor

2、過濾原理:真空泵起動(dòng)后約10秒內(nèi),可將真空負(fù)壓罐內(nèi),抽成一個(gè)不小于91.2kpa(684毫米汞柱)的負(fù)壓腔,然后接通電磁閥3或5在壓力差的作用下,使濾盤內(nèi)的液體很快透過濾紙,達(dá)到脫水的目的。

2. Working Principle: Within around 10s after the vacuum pump is started, make a vacuum capacity with the pressure of not lower than 91.2kpa (684mm mercury column) in the vacuum negative pressure jar. Then connect the electromagnetic valves 3 and 5. Under the action of pressure difference, the liquid in the filter disk permeates into the filter paper very quickly so that the purpose of dewatering can be served.

3、結(jié)構(gòu)特點(diǎn):

3. Structural Feature:

本機(jī)結(jié)構(gòu)簡單、緊湊,真空系統(tǒng)工作可靠,具有較高的真空度, 為防止真空負(fù)壓罐內(nèi)的液體進(jìn)入真空泵,在器內(nèi)設(shè)置了上下接點(diǎn),當(dāng)液體達(dá)到預(yù)定高度時(shí)真空泵自動(dòng)停車,同時(shí)打開放氣電磁閥,待液體排完后自行起動(dòng)。

This machine features simple and compact structure, reliable operation of vacuum system, and high vacuum degree.

To prevent the liquid in the vacuum negative pressure jar from entering the vacuum pump, upper and lower connection points are designed for this machine. When the liquid reached the preset height, the vacuum pump stops working automatically. At the same time, open the air-release valve. It starts up automatically after all the liquid is discharged.